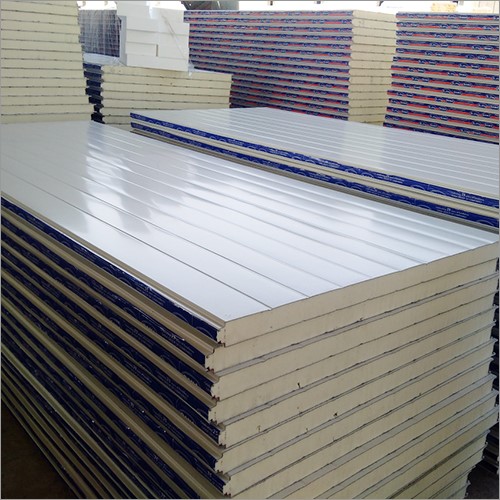

SRI and LRV value for roofing sheets and Sandwich panels

A cool roof is defined by a combination of high reflectivity and high light reflectance value, according to most roofing industry experts. But the question has always been how much is too high, and what mix of the two provides the best results.

Solar Roof Index (SRI)

Lawrence Berkeley National Laboratory scientists created SRI. Roof buyers won’t have to scratch their brains trying to figure out if a high reflectivity and low emissivity are better or worse than a medium reflectivity and high emissivity since SRI combines the attributes of reflectivity and emissivity into a single, easy-to-read, standardised value.

SRI is a scale of 1 to 100 that measures a roof’s overall thermal qualities and is computed using a sophisticated formula outlined in ASTM E 1980. A standard black (reflectance 0.05, emittance 0.90) is defined as 0 while a standard white (reflectance 0.80, emittance 0.90) is defined as 100. Some hot roofs, on the other hand, might have negative values, and some white thermoplastics and white roof and sandwich panel coatings have had scores of 104 to 110.

SRI as a reporting mechanism for cool roof and sandwich panel data will most likely take some time to catch on. Most manufacturers still present emissivity and reflectivity statistics separately in their literature, but the Cool Roof Rating Council, which evaluates and marks cool roofing products, has started adopting the metric while keeping the reflectivity and emissivity values distinct.

The SRI values of various roofing methods vary. Aluminium pigments are added to asphalt cuts and emulsions in asphalt coatings, for example, to give them sun reflection index (SRI) values of 21-30 on a scale of 0-100.

Light Reflectance Value (LRV)

The percentage of light reflected by a paint colour on a surface is measured by the Light Reflectance Value (LRV). LRV is used to assess how dark or light a paint colour will seem by using a scale that spans from 0 to 100 percent.

Because paint colours have a considerable impact on a space’s natural and artificial light, as well as the heat it reflects and absorbs, the LRV rating must be taken into account.

Paint colours with a low LRV, for example, are often dark and absorb a lot of light and heat. Paint with a greater LRV, on the other hand, is often lighter in colour and functions by reflecting light and heat.

What should you know about LRV paint choice?

Because lightweight wall systems are more subject to external influences like heat and light, choosing paint colours with a higher LRV will assist prevent against thermal movement and damage.

Because DANA understands how lightweight wall systems differ in their ability to decrease heat variation and thermal stress, they have varied coating techniques based on the surrounding substrates.

DANA has supplied a list of LRV constraints on several typical substrates to protect property occupants from cracking of finishes, breakage of construction connections, and increased interior effect of variable exterior temperatures.

DANA STEEL is a leading manufacturer of various steel products, covering a wide range of products and serving thousands of clients across the globe, at Dana Steel we ADD VALUE TO STEEL. Our products are proudly MADE IN UAE and exported to more than 45 countries across the globe. Sandwich Panels, Profile Sheets, Decking Sheets, Aluminium Panels, Composite Panels, Z Purlins, C channels, Metal Lintels, roofing sheets, Fencing Sheets, Steel sheets, stainless steel.

Plot No: 5325494 ,Saih Suaib-3

City: Dubai

Country: United Arab Emirates [U.A.E.]

Phone: 00971-4-2217273

Email: Info@danasteel.com

Fax: 00971-4-2215940

Facebook/Instagram/Twitter: @danasteeluae

Whatsapp: +971507983153