How Can Vertical Farming Aid Food Security During A Global Food Crisis?

Food production is a significant issue for all countries due to an increasing global population. However, the amount of land suitable for conventional farming has decreased due to urbanisation and climate change. When it is difficult or unpredictable to obtain wholesome food, it is said to be experiencing food insecurity.

Large-scale food production can be accomplished by vertical farming in a lot less space than through conventional agriculture. By producing crops in a stacked configuration in factory-like areas, vertical farms require less agricultural land overall.

Plants are often cultivated hydroponically (without soil) in vertical farms, which allows for precise nutrient delivery to crops and eliminates problems with fertilisers. When compared to crops grown in the field, vertical farming can generate crops with up to a 10x higher yield while using 95% less water.

Use Of Water Chillers In Vertical Farming

Natural growing circumstances can be mimicked technologically, making it possible to continuously regulate variables like light, temperature, and humidity. This makes it possible to grow crops all year round, regardless of the season or the weather. As usual impediments like bad weather are avoided, this kind of indoor farm can also offer crop harvests that are guaranteed.

Despite the fact that Dana water chillers can be used in hydroponic systems, where large-scale water chilling may be necessary to reduce the likelihood of algae growth as a result of heating the nutrient solution.

Due to its location in urban settings, vertical farming has the potential to disrupt the conventional food supply chain. Many steps in the supply chain can be skipped, allowing the product to be sold directly to customers and lowering the food supply’s carbon footprint. Having nearby vertical farms could be crucial in guaranteeing food security during situations like the worldwide pandemic, where the food supply was severely affected. Pesticides are not necessary for vertical farming; some farms even make use of beneficial bugs.

Despite this, vertical farming has its own share of difficulties. Vertical farms cost a lot of money. Due of the need to purchase land, water, lighting, and even carbon dioxide from vendors, the startup expenses and energy needed are not inexpensive. Traditional agriculture does not have to pay for this.

The use of energy-efficient LED lighting, which can even be regulated remotely to cut down on energy usage costs, can minimise lighting expenditures. Water can be collected and recycled, which reduces water bills as well. Although labour expenses for vertical farms can be high as well, technology can help these businesses cut costs.

Another issue is the lack of public knowledge on vertical farming, this means the public may be scared of crops grown in this manner. But raising awareness and information can help to tackle this public hesitation. The technology needed for vertical farming is developing rapidly, this allows prices to be lowered, making vertical farms less expensive to set up and run.

As a result, vertical farming has the potential to significantly boost food output. Additionally, because vertical farms are so small, they can be erected virtually anywhere, eliminating the need for them to just be used in abandoned factories that have been converted to farms. Home farming enables individuals to grow their own food, and corporations can even set up vertical farms inside their structures or on their roofs.

What will be the role of vertical farming in ensuring a safe and steady stream of food in places of crisis?

Food security can and will be addressed through vertical farming. Vertical farms are able to produce enormous yields, but they can also produce high-quality food because the regulated atmosphere is constantly monitored.

Less food is wasted during transportation to supermarkets and local food supplies are ensured through shorter supply chains and routes. Additionally, the viability of vertical farming as a large-scale food production technique rises with the current advancements in vertical farming technologies, such as improved LEDs and automation.

Although vertical farming won’t entirely end the world’s food shortage, it can be used in conjunction with other methods to reduce the demand for arable land. Vertical farming won’t directly address this issue because a 70% increase in food production is required, but it will undoubtedly have a significant impact on the food supply business in the years to come.

About us:

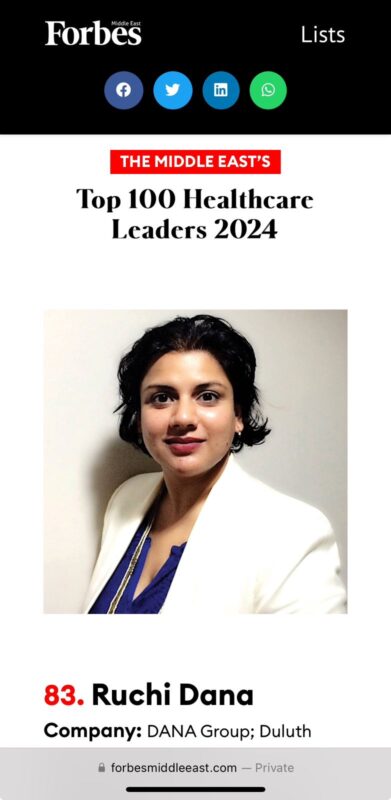

Established in 2001,DANA WATER HEATERS & COOLERS FACTORY LLC,is one of the manufacturing concerns of prestiguous DANA GROUP [www.danagroups.com] . Since it’s inception the company has endeavored to provide premium quality heating,cooling & refrigeration solutions to it’s valuable clients.

With it’s head office situated within 10 minutes from Dubai International Airport,and it’s manufacturing faciltiies in Al Quoz Industrial Area 1 (Dubai) & Al Jurf Industrial Area (Ajman),we are fully equipped to meet the demands of the GCC,Gulf & Arab markets.

Our firm is an experienced Manufacturer, Exporter, and Supplier of Industrial Air Cooled Water Chillers,Tank Water Cooling System(Tank Water Chiller),Stainless Steel Drinking Coolers,Heaters,Swimming Pool Heat Pumps & Cold Room Refrigeration Solutions from Dubai, U.A.E. Our Units are designed to be highly efficient, consume less power and deliver reliable output. We are capable of delivering any order with reliability,on-time delivery & prompt after sales service. Dana Group has been catering to Dairy chiller and coldroom industry, Poultry Farm chiller and coldrooms, Livestock production coldrooms and water chillers, Hydroponic farm water chillers and coldrooms.

Customers can obtain our exclusive collection of heating & cooling solutions at modest rates. The Products we offer are acclaimed for their elegant designs, good spaciousness, and excellent finish. As a reliable Manufacturer, Exporter, and Supplier from Dubai, U.A.E., we ensure customers get a quality assured product. Hence, our quality auditors check our products on various parameters before the final delivery.Our products are exported to Africa,Oman (Ibri, Salalah, Muscat, Sohar, Nizwa, Barka),Bahrain,Saudi Arabia,Kuwait,Qatar ,Jordan and other neighboring Gulf/GCC Countries .We have our dedicated installation & after sales team to cover installations across UAE( i,e Dubai,Ajman,Sharjah,Al Ain ,Abu Dhabi,Fujairah,Ras Al Khaimah,UAQ) and GCC countries including Oman (Salalah, Muscat, Sohar, Nizwa, Barka, Ibri)

Dana Water Heaters And Coolers Factory LLC

Contact Person : Mr. Ankur Singh

Address :-Head Office – Suite No 405-406,B-Block Centurion Star Bldg,Opp Deira City Center, Dubai – 40743, United Arab Emirates

Factory – Plot # 369-B166,Al Quoz Industrial Area #4,Dubai , UAE

Contact No. : +971-4-2217273 (Landline)

Email : info@danagroups.com / info@danawatercoolers.com