HRPO (Hot Rolled Pickled and Oiled) and its use in the automotive industry

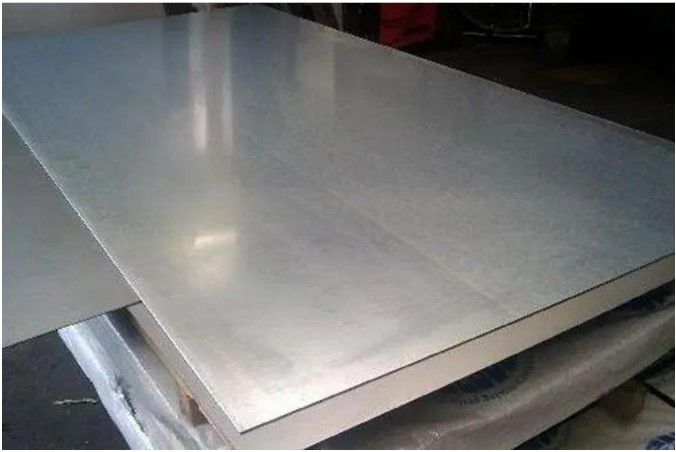

HRPO (Hot Rolled Pickled and Oiled) steel is steel that has been cleaned of impurities and unwanted materials, such as stains and rust, through the process of pickling. The steel is then oiled to prevent rust and other forms of corrosion, which provides an additional layer of protection for the material.

HRPO steel is commonly used in the manufacturing of automobiles, appliances, and construction materials. The process of pickling and oiling the steel improves its surface finish and makes it more ductile, which allows for better forming and welding of the material.

There are a few benefits of using HRPO steel. The cleaning process of pickling removes any surface impurities and also removes the scale on the steel produced during the hot rolling process, which can make the surface of the steel appear dark and mottled. This improves the surface finish of the steel and makes it more visually appealing. The oiling process also helps to prevent rust and corrosion, which can extend the life of the material.

It’s also important to consider that pickling process makes the steel surface more uniform, wich results in better final product. This can be especially important in applications where precise measurements and tight tolerances are required.

It’s also important to note that HRPO is a low cost material as a result of hot rolling process and pickling process, making it a cost-effective option for many applications.

use in the automotive industry

In the automotive industry, HRPO steel is used in a wide range of applications, including body panels, structural components, and underbody parts. The improved surface finish of the steel allows for better paint adhesion, which can improve the appearance and durability of the finished product. The added ductility of the steel also allows for improved formability, which can make it easier to stamp and form the steel into the desired shapes.

The oiling process that is used on HRPO steel also makes it more resistant to corrosion, which is important in applications where the steel will be exposed to harsh environments or road salt. This can help to extend the life of the component and reduce the likelihood of rust and other forms of corrosion.

The use of HRPO steel in the automotive industry is also cost-effective, as it is a relatively inexpensive material compared to other types of steel. This can help to keep the overall cost of manufacturing vehicles down.

It’s also important to note that the steel can also be further processed to reach a final product. HRPO steel often receives a cold roll operation, which helps to improve the strength and surface finish of the steel, making it more suitable for certain applications.

In summary, HRPO steel is commonly used in the automotive industry due to its cost-effectiveness, improved surface finish and added corrosion resistance, good formability and stamping processability.

About Us

DANA Steel (www.danasteel.com) is an ISO 9001:2015 certified company, with the rich experience of around three decades, we have always thrived hard in order to bring revolutionary changes to the steel industry; We have our state of the art Cold Rolling Mill (CRM Complex) Situated in DIC (Dubai Industrial City) we proudly manufacture our products in Dubai, UAE.

Our market extends over a wide demographic as we export over products to around 50 countries including counties from the Indian subcontinent (Bangladesh, India, Nepal); South-East Asian countries (Indonesia, Thailand, Vietnam); Middle-East countries including members of GCC (GCC-Saudi Arabia, Bahrain, Kuwait, Jordan and Oman (Ibri, Salalah, Muscat, Sohar, Nizwa, Barka). We also have our markets extended to Africa (Djibouti) and South America. With our constant commitment to customer contentment, we are able to provide competitive prices and faster shipment to all of our valuable clients.

Feel free to contact in case of any enquiry. Listed below are the mediums through which you can reach us out!

WhatsApp – +971507983153

Tel – 0097142217273

Email – info@danagroups.com / info@danasteel.com