Steel slit is a method of metal cutting that uses very sharp rotary blades to cut large rolls or folds of sheet metal as per ASTMA653 and JIS G3302. They are cut in length into a big coil to produce shorter strips to achieve straight lines. Circular blades are in need of cutting the slitted galvanized coils while the slitter is working. These are called “knives” and can be shifted to various widths.

The broken pieces are cut to a smaller width and the same length is kept. Until slitting the initial rollers are placed on a circular drum, until they are flattened on a slitting leveler. Slitted galvanized steel coil through a number of widths. Each application requires its own slitting capability for galvanized steel coils.

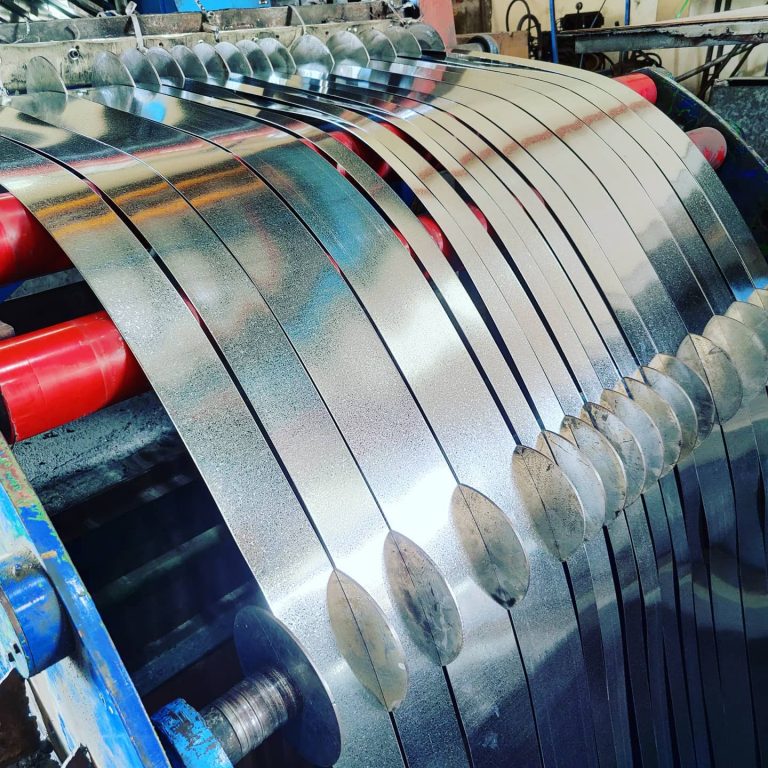

Slitted Galvanized (GI) Coils

Slitting gi coil is commonly used for both galvanized slit steel coil and sheet. The blades should be designed for the job at hand for any job. Mastery is the game’s name for slitting steel rolls and coils.

Galvanized Coils Slitting Characteristics:

Slitted galvanized coils are highly resistant to corrosion with their chrome content according to ASTMA653 and JIS G3302, especially when in normal atmospheric conditions. It is capable of forming passive, tough and strong chromium oxide barriers. And its high content of chromium enables the grade to renew particularly quickly the thin protective layer. Galvanized Slitting Coils are ductile and are bent, pressed, drawed and headed.

Splitting galvanized coils are better than many ferritic steels withstand chloride-induced stress cracking. In the presence of organic dilute acids and many alkalis, it is also well protected against corrosion. It is also resistant to nitric acid and suitable for some chemicals.

Slitted coils for mild corrosion are ideally suited. The galvanized steel is much cheaper. For non-critical indoor settings, cutting coils are also a safe option. Even at high temperatures, galvanized steel provides strong oxidation resistance.

Hot and Cold Work for Galvanized Slitting Steel Coils:

In the Temperature range from 1500 to 1900 degree F, Galvanized Slitting Coils as described in ASTMA653 and JIS G3302 may be heated. It can be generated by methods like forging after reaching a uniform temperature. Its grade, if exposed to high temperatures for a long time, is prone to excessive heat generation which reduces the ductility. Air cooling for room temperature is usually fast. Slow cooling at less than a thousand degrees F can lead to bitterness. When heat is treated, galvanized steel will not harden remaining ductile.

Slitting of Hot Dip Galvanized (GI) Steel Coils

Galvanized Steel Slit Coils Applications:

GI coil also provides great strength and an attractive finish, easy to maintain and inexpensive. Galvanized steel is therefore mostly chosen because of its aesthetic quality and its corrosion resistance. In a wide variety of applications, galvanized steel slit coils are used. These include milk production machines, cryogenic cooling instruments, hygiene fittings, pumps, chemical equipment, hopper linings, oil filter boards, beer barrels, burning vessels, evaporators, automatic components, furnace trimming and molding devices, kitchen cables, tube cones, tobacco machinery, hardware builders, slippers, tubes and more.

DANA Steel based in UAE is the greatest maker and stockiest of slitted Coils and Sheets. We are slitted gi coil supplier in uae and supplies in the whole Middle East covering the U.A.E and GCC area. We supply galvanized slitted coils and sheets to Africa, UAE (Dubai, Ajman, Sharjah, Abu Dhabi, Rak, UAQ, and Al Ain), Oman (Salah, Muscat, Ibri, Sohar), Saudi Arabia, Kuwait, Bahrain, and other Middle East areas.

Credit – https://danasteel.com/slitted-galvanized-coils-as-per-astma653-jis-g3302/